Rig Partner offers a comprehensive and experienced solution to simplify the rig intake process. Our team of qualified experts provides technical, HSE&Q, and commercial resources to ensure your rig is not only compliant but also fit for your operation

We go beyond just acceptance testing and commencement verification, conducting a thorough evaluation of the rig’s management systems, maintenance systems, training, and historical performance to minimize risk and impact on health, safety, and environment. Our Rig Intake Management System is well-proven, making us the perfect partner for exploration and production drilling units worldwide, in both shallow and deep waters.

Rig evaluation and selection

- Tender preparations and ITT

- Tender review, evaluation, rig surveys (of short listed rigs)

- Rig selection

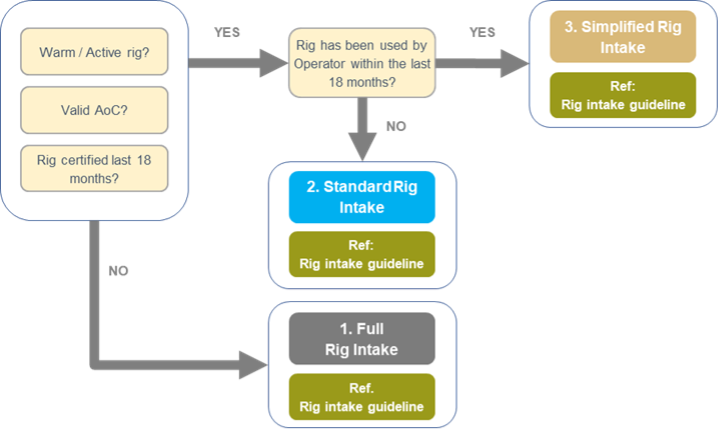

Rig Intake Process

Compliance verification work process – key elements

- Master Verification Plan (MVP)

- Rig Intake Process integrated with Client’s company specific activities

- Strives for a good and efficient process with Drilling Contractor

- Practical approach

- MVP based verification/work meetings with Drilling Contractor

- Onboard inspections

- Our databases for PSA audits and Incident investigations used as input to verification scope onshore/offshore

- Rig Acceptance Test

- Follow-up and close-out of Action Log

- Inspection activities during operation

Let us handle your rig intake from start to finish with services like contract review, ITT preparation, pre-qualification of contractors, evaluation procedures, and contract management. Trust us to make rig sourcing and contracting stress-free and efficient. Contact Rig Partner today and experience a seamless rig intake process

We offer support with a range of complementary services, including

- GAP-studies for Well Control Manuals

- Bridging document for manuals and procedures

- Applications for Consent to Drill